Authors: Youssef Elyaalaoui, Flight Physics Engineer at Dufour Aerospace, and Jim Bungener, Application Engineer at Flexcompute

Figure 1: the Dufour Aerospace AERO 2

The Dufour Aerospace AERO2 is a 6 meter wingspan, 4 meter long VTOL UAV (Vertical Take Off and Landing Unmanned Aerial Vehicle) designed to carry a 40kg payload with a range greater than 400 kilometers. Designing such a unique vehicle to be first to market in its weight class is no easy task. What’s the big deal? Well, aerodynamically we need to draw up a vehicle that has certain efficiency in cruise. A big percentage of the total mass of electrical and hybrid VTOL aircraft is in the propulsion system. So the more efficient the aircraft is, the more we can minimize the mass of the energy storage (batteries and fuel). This will allow for a higher payload without which the system is commercially non-viable.

On the other hand, for the aircraft to also have vertical take-off and landing capabilities it needs to transition safely from hover to forward flight and back by tilting the wing. In this flight phase the propeller slipstream dictates the flow conditions on the wing and control surfaces, which imposes a completely different set of aerodynamic requirements and challenges.

Achieving a viable solution requires leveraging all the latest simulation and design tools available and pushing our design processes to be as efficient as possible. Our team cannot afford to rest on our laurels, and must continually innovate, not only in our products but, more importantly, in our processes.

One of the key innovations being implemented is the advancement of vehicle simulations earlier in the design process. By incorporating high-level physics simulations at these initial stages, it becomes possible to identify design shortcomings while the design envelope remains relatively open. As the design progresses, more decisions are locked in, thereby reducing flexibility. Early identification and resolution of design issues provides greater freedom for refinement and leads to more holistic improvements, ultimately enabling faster development of superior designs. This proactive approach significantly reduces the risk of major setbacks that would necessitate revisiting prior decisions and repeating earlier phases. The overarching objective is to deliver to the flight testing team a product that performs as expected, one for which the aerodynamic behavior is well understood across the entire flight envelope, and that meets all test and certification requirements without unforeseen complications. Achieving this objective minimizes the need for costly redesigns after prototype construction and testing have already occurred.

A critical enabler of a well-characterized performance envelope is improved computational fluid dynamics (CFD) simulations. By performing high-accuracy simulations across a wide range of flight conditions, it becomes possible to predict the aerodynamic performance of a design with an exceptional degree of confidence. This is particularly valuable for the structural engineering team, which benefits from more accurate data regarding the maximum loads the vehicle must endure, as well as for the flight controls team, which can develop more realistic models of in-flight behavior.

At Dufour Aerospace, the Flight Physics Department is responsible for meeting these ambitious goals. To support this effort, the team has, for many years, utilized the Flow360 solver developed by Flexcompute. This tool has been employed to analyze everything from preliminary conceptual sketches to highly detailed simulations of complete aircraft.

Flow360 is a high-performance, GPU-native solver that functions as part of an integrated cloud-based suite. This platform facilitates a seamless workflow encompassing meshing, simulation, and postprocessing for all CFD-related tasks.

Leveraging Flow360, the team has developed comprehensive aerodynamic databases that capture a broad range of variables including angle of attack, sideslip angle, airspeed, propeller RPM, and various control surface deflections, These databases are repeatedly updated as the design evolves. The toolchain’s speed, throughput, and accuracy have enabled the generation of highly reliable results within significantly compressed timelines.

As the AERO2 geometry reaches a more mature state, the focus has shifted to exploring the vehicle's behavior during dynamic phases of flight. Current investigations, for instance, include analysis of dynamic derivatives involving pitch oscillations, where the aircraft rotates about its lateral (Y) axis.

Figure 2: AERO2 pitch oscillations with vortices shown

Figure 2: AERO2 pitch oscillations with vortices shown

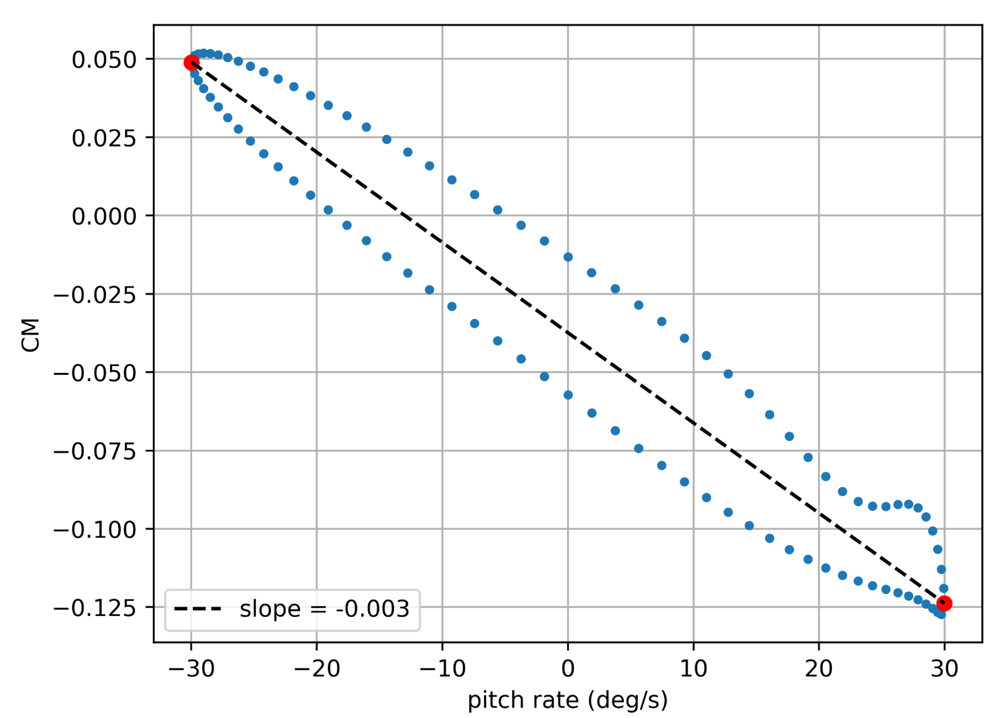

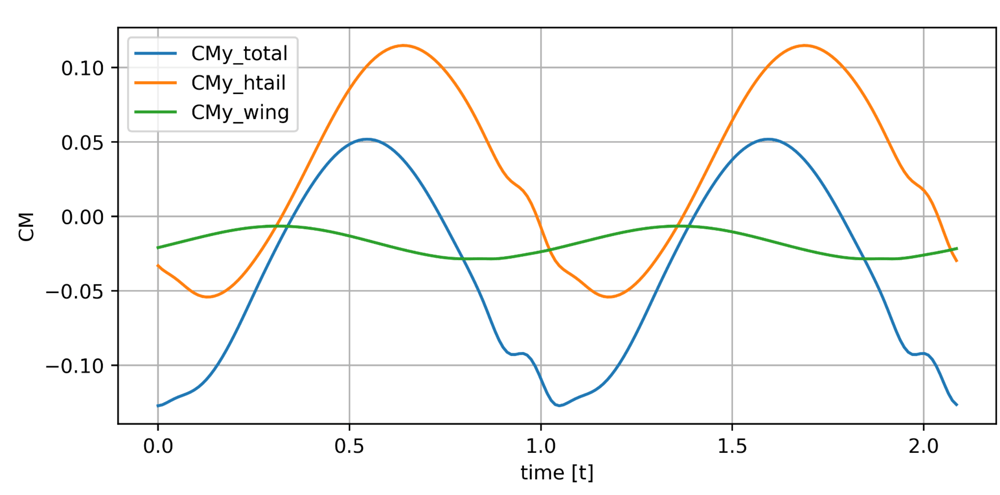

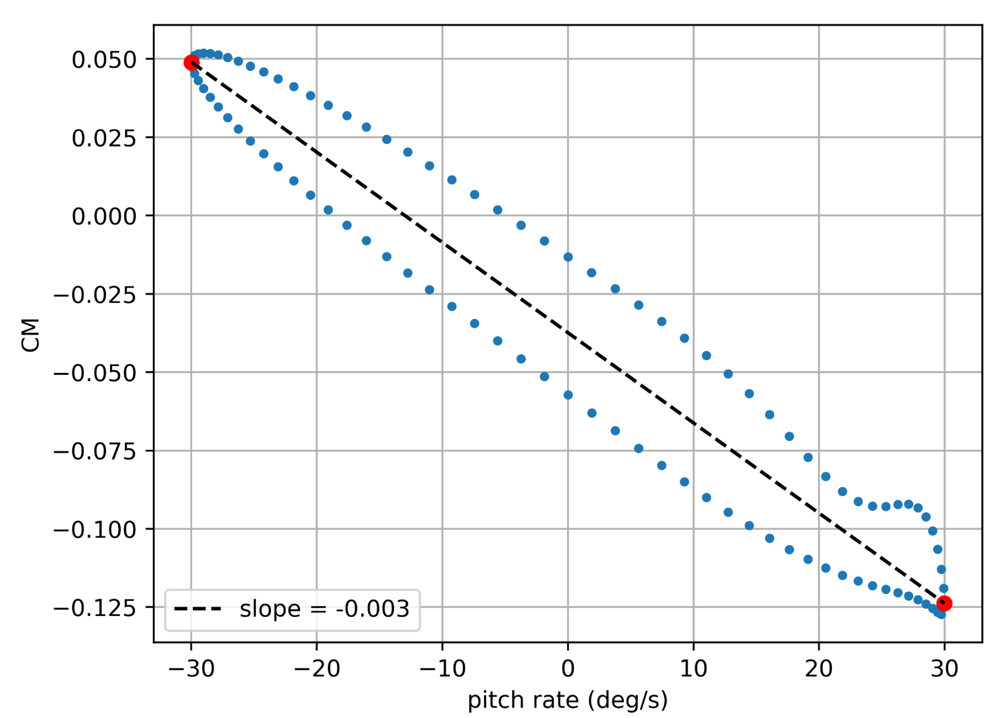

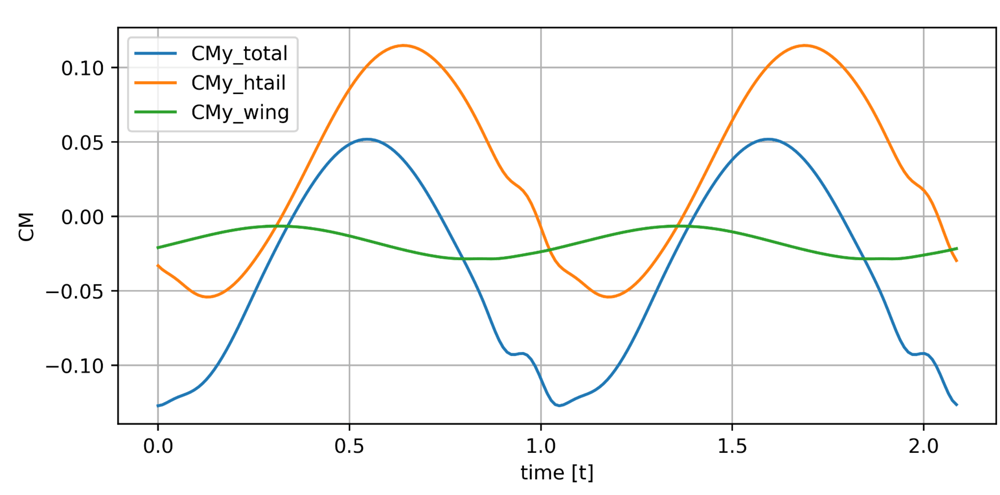

As illustrated in figures 3 and 4 below, we can identify a nonlinearity in the pitching moment of the airplane as it goes through the oscillation cycle.

Figure 3: AERO2 pitching moment vs pitch rate

Figure 4: Detailed view of AERO2 dynamic derivative pitch oscillation. Red dots are when the airplane is horizontal (0 pitch)

Figure 4: Detailed view of AERO2 dynamic derivative pitch oscillation. Red dots are when the airplane is horizontal (0 pitch)

Doing such simulations in the wind tunnel would be prohibitively expensive, both in terms of time and money. By staying in the virtual world and doing all our CFD simulations with Flow360, we can efficiently study and analyze complex scenarios in depth. This approach enhances our understanding of the physics involved and allows us to evaluate various solutions, ultimately achieving our objective of delivering superior designs more quickly.

Figure 5: Pitching moment on various subcomponents of AERO2. Giving us deeper insight into the cause of the instability.

To give you a sense of scale, these results are taken from runs done on a 31 Million node mesh with Y+ values less than 1 on the vehicle. The results you see above were generated in less than 20 minutes on the Flexcompute NVIDIA B200 GPU based cloud infrastructure.

Lower-fidelity methods would not have adequately captured the complex physics associated with such nonlinearities. Identifying such behaviors at an earlier stage with high fidelity allows us to better model and tune our controls to ensure stability and performance. Traditionally, these types of behaviors might only have been identified during flight testing, at a stage when resolving them efficiently would no longer be feasible, due to significant time and financial resources, substantially impacting both budget and schedule.

Besides all the aero performance databases requested by the flight control team and the structural loads requested by the structural teams, Dufour Aerospace is also now looking forward to doing some acoustics work with Flow360. Many certification authorities are now allowing CFD data as part of the certification process and we plan on fully taking advantage of that on our road to certification.

.png)