In this case study, we demonstrate loading a foundry PDK, performing RF and optical simulations, conducting time-domain analyses, and generating fabrication-ready layouts — all within a single interface. The example features an ultra-high-speed electro-optic modulator in thin-film lithium niobate (TFLN).

Background

Electro-optic Mach-Zehnder modulators (EO-MZMs) are essential in photonic integrated circuits (PICs), particularly for high-speed optical communication. These devices modulate light by changing the refractive index of a waveguide in response to an applied electric field—a process that requires careful coordination of electrical and optical properties.

Designing such devices traditionally involves fragmented workflows: separate tools for layout, electrostatic modeling, optical simulation, and data analysis. These disconnected steps can lead to inefficiencies, longer development cycles, and integration errors.

Explore the complete example: Electro-Optic MZM Example in PhotonForge Documentation

Challenges

To design and optimize EO-MZMs, engineers need to:

-

Accurately simulate the electro-optic effect, including voltage-induced refractive index changes.

-

Understand the interaction between RF electrodes and optical waveguides.

-

Quantify performance metrics like extinction ratio, insertion loss, and phase modulation efficiency.

-

Iterate rapidly on device geometry, electrode configuration, and material stack-up—all while ensuring fabrication readiness.

Traditional limitations:

-

Separate solvers for electrical and optical domains make co-simulation cumbersome.

-

Manual data exchange between tools increases the chance of error.

-

High computational costs due to 3D field simulations.

-

Limited layout-driven simulation capabilities inhibit rapid prototyping.

Solution with PhotonForge

PhotonForge unifies layout, electrostatic, and full-wave optical simulation within one cohesive platform. Using the Tidy3D engine, PhotonForge allows for:

-

Electro-optic co-simulation using voltage-dependent permittivity mapping

-

GPU-accelerated FDTD simulation for rapid optical modeling

-

Scriptable Python interface for parameter sweeps and design automation

-

Drag-and-drop layout tools for fast, fabrication-aligned design creation

-

Direct GDS import/export for seamless foundry integration

-

3D field visualization of electric and optical field distributions

Design details

The EO-MZM design in this case study includes:

-

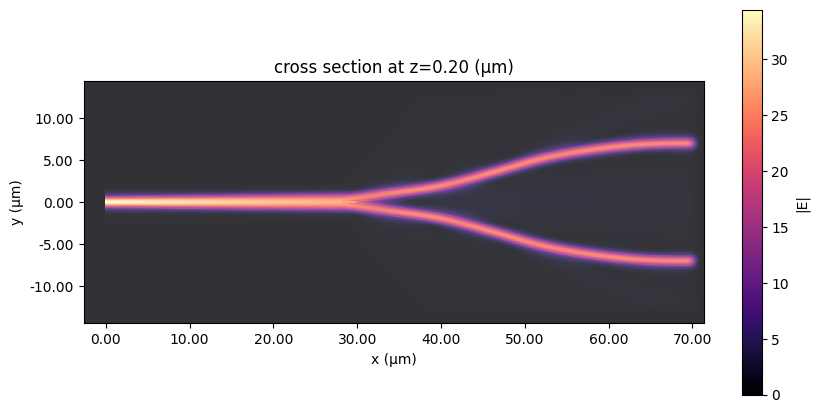

Y-splitter: An input waveguide splits the optical signal into two arms.

-

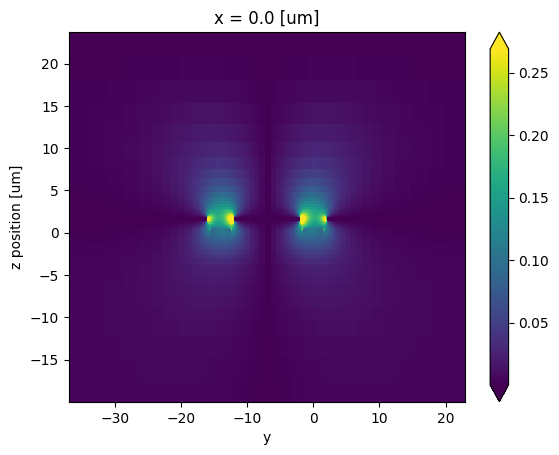

Phase modulator arms: Each arm contains a straight waveguide surrounded by metal electrodes. A voltage applied to these electrodes induces an electric field that modifies the local refractive index.

-

Whole device: Integrate the edge couplers with the MZM and create a complete device.

Simulation process

-

Layout construction:

The entire modulator geometry, including optical waveguides, cladding layers, and electrode geometries, is created in PhotonForge using its layout editor or scriptable Python interface.

-

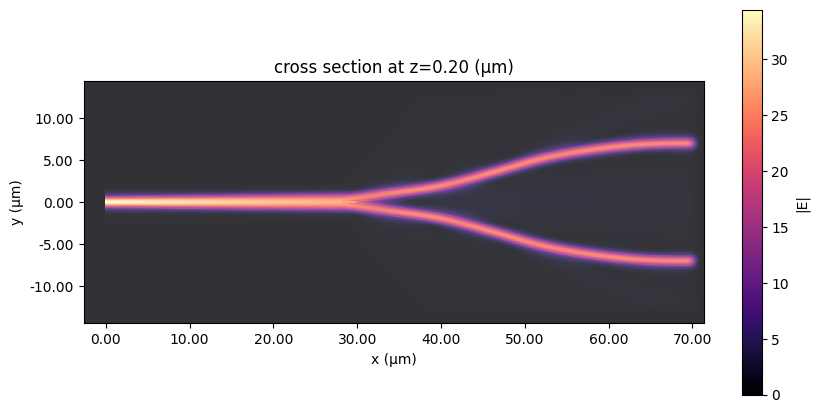

RF photonic solver:

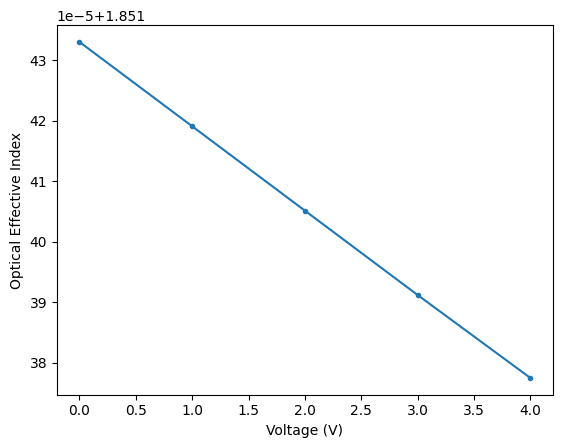

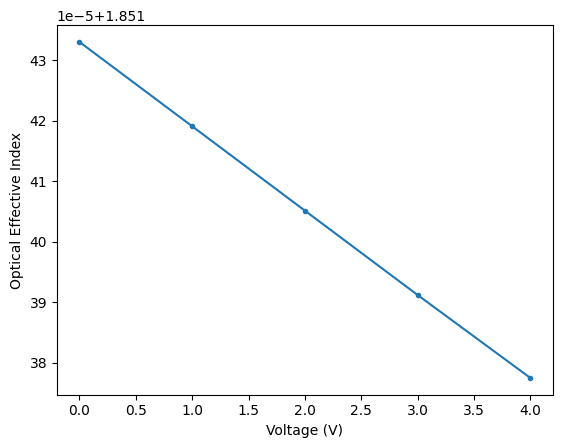

PhotonForge calculates the electric field distribution generated by the applied voltage. From this field, the change in refractive index is computed using the linear electro-optic (Pockels) effect for the selected material (e.g., LiNbO₃, silicon, etc.).

-

Permittivity mapping:

The induced index change is transformed into a spatially varying permittivity map, which is then used to perturb the optical domain for accurate co-simulation.

-

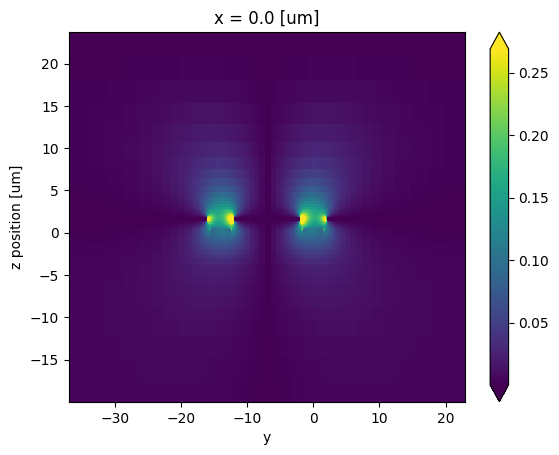

FDTD Simulation:

The perturbed structure is simulated using Tidy3D’s GPU-accelerated FDTD solver to analyze how the modulated index distribution affects light propagation.

-

Result analysis:

The output fields are analyzed to determine: insertion loss, extinction ratio (ER), phase shift efficiency, and output intensity modulation vs. input voltage.

Results

Using PhotonForge, the simulated EO-MZM achieved:

-

High extinction ratio: ~20–30 dB depending on phase mismatch

-

Insertion loss: Maintained below 1 dB with optimized tapers

-

π-phase shift voltage-length product (VπL): Tunable via electrode spacing and material selection

A full 3D model's complete co-simulation runtime is under 10 minutes. The in-built visualization tools provide 3D overlays of both the optical and electric fields, enabling intuitive debugging and optimization. Cross-sectional slices and field animations provide insights into wave interference dynamics and loss mechanisms.

Advantages Over Traditional Tools

| Feature |

Traditional Workflow |

PhotonForge |

| Electro-optic co-simulation |

Manual, disconnected tools |

Fully integrated |

| Layout-to-simulation |

Manual translation |

Automated, layout-driven |

| GPU acceleration |

Often CPU-bound |

Native GPU support |

| Design automation |

Limited |

Python scripting |

| 3D visualization |

Basic or missing |

Advanced GUI with overlays |

| Foundry-ready PDK support |

Often custom-built |

Built-in and customizable |

Conclusion

This case study illustrates how PhotonForge transforms the workflow for designing and simulating electro-optic modulators. With a unified environment that supports full electro-optic co-simulation, high-performance GPU-based FDTD solvers, and fabrication-ready layouts, engineers can now:

-

Rapidly iterate on device concepts

-

Confidently evaluate performance

-

Streamline handoff to fabrication

Whether you're developing cutting-edge optical interconnects or optimizing modulators for quantum applications, PhotonForge allows you to move faster, with accuracy and confidence.

Explore the example

Electro-Optic MZM Example in PhotonForge Documentation

.png)