In the fast-paced world of electric vehicle (EV) development, NIO (NYSE: NIO), a global leader in smart EVs, was faced with a significant challenge: traditional computational fluid dynamics (CFD) simulations were too slow, requiring hours—or even days—to evaluate each design iteration’s impact on drag and aerodynamic performance. To overcome this bottleneck, NIO turned to Flexcompute’s revolutionary Flow360, a GPU-native CFD solver that has drastically changed the way they approach aerodynamic optimization.

The Power of GPU and AI in CFD: Transforming Aerodynamic Design

Building on the industry-leading speed of our GPU Native solver, we've enhanced it with integrated AI prediction, revolutionizing the way NIO engineers optimize vehicle aerodynamics. Flexcompute’s AI-powered solution leverages a large-scale foundational model pre-trained on flow physics, enabling NIO to predict aerodynamic performance with incredible speed and accuracy.

Unlike traditional CFD, where engineers would have to wait hours or days for each simulation, Flow360’s integrated AI capabilities can deliver results in seconds, with predictions that are accurate within three orders of magnitude of drag. This allows NIO to explore tens to hundreds of design concepts in a single day—an achievement previously impossible with conventional simulation methods.  Figure 1. Results from collaboration with NIO to explore AI prediction on real vehicle aerodynamics

Figure 1. Results from collaboration with NIO to explore AI prediction on real vehicle aerodynamics

The AI model swiftly adapts to NIO’s specific vehicle designs by using few-shot learning, eliminating the data-heavy demands typically associated with conventional AI systems. This allows NIO engineers to validate design iterations in real time, making rapid, data-driven decisions that accelerate product development and reduce time to market.

High-Fidelity CFD Simulation with Flow360

Flexcompute’s Flow360 solves the speed and precision problems traditionally associated with CFD simulations. By harnessing the power of GPU-native technology, Flow360 performs simulations up to 10-100 times faster than legacy methods while maintaining the accuracy needed for fine-tuning aerodynamics.

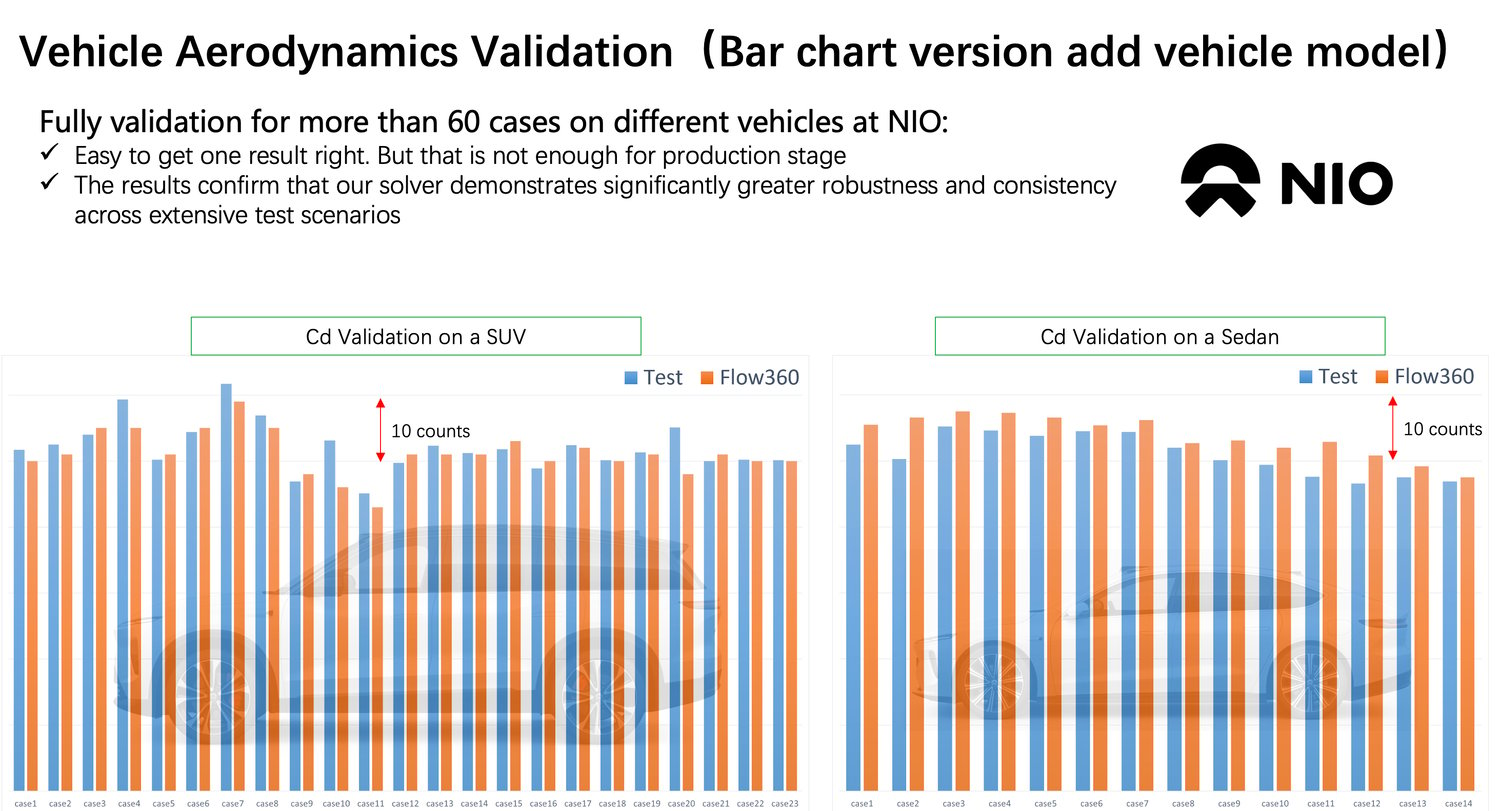

NIO has used Flow360 to conduct over 60 fully validated simulations across various vehicle types, confirming that the platform provides robust results in various aerodynamic scenarios. This validation proves Flow360’s reliability and ability to deliver real-world insights that align closely with physical testing, such as wind tunnel data.

Key Differentiators of Flow360

-

Fastest Speed and Efficiency: Flow360’s simulation time is 10-100 times faster than traditional methods, completing complex simulations in just an hour on 8 L20 (10 mins on 8 H200)

-

Unparalleled Accuracy: More than 94% of simulations show less than 3% deviation from physical wind tunnel tests, ensuring that design decisions are based on reliable data. The results below confirm that Flow360 demonstrates significantly greater robustness and consistency across extensive test scenarios.

-

Cost Reduction: For a given hardware investment, NIO can get more simulation results due to the fast speed and better scalable code. On average, it sees a 60% cost reduction per simulation run. At the same time, high accuracy reduces the need for costly and time-consuming physical prototypes, cutting down on both R&D costs and development timelines.

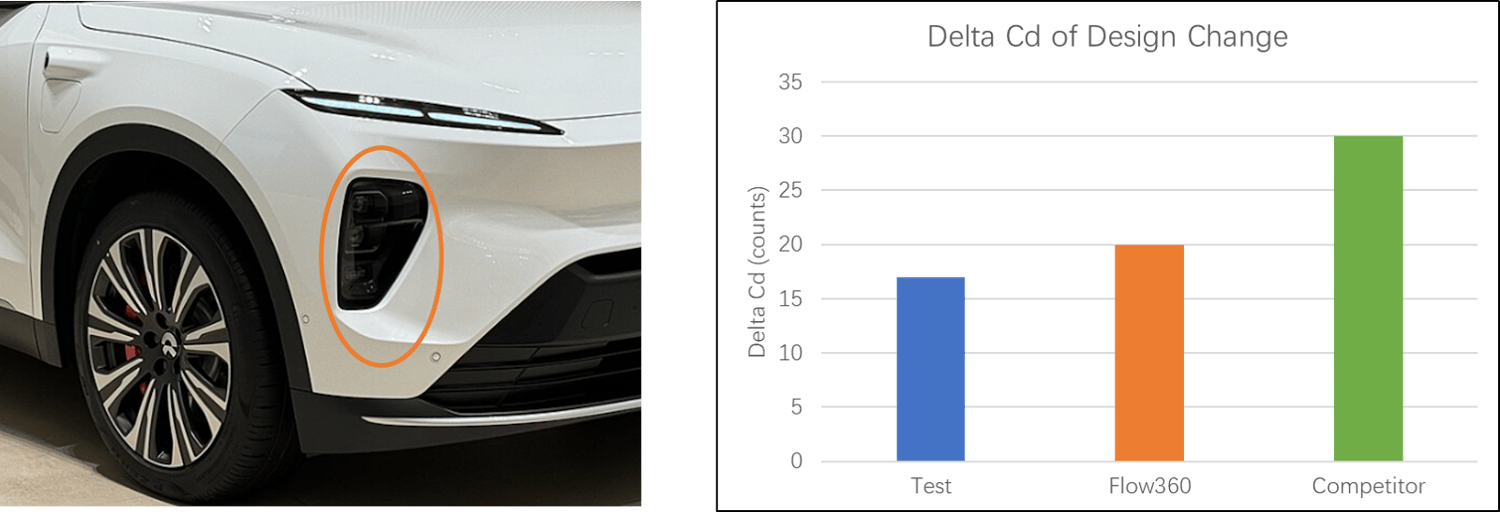

The importance of Delta Cd and Trends

One of the most significant impacts of Simulation tools in Automotive Aerodynamic design is accurate trend prediction. As aerodynamics are working to refine their designs they rely heavily on CFD to predict the right delta Cd and right trends. This gives them confidence that their ideas and recommended changes will help meet the target. Oftentimes trend prediction is delicate as small separations can have a big impact on the design. CFD Analysts and Aerodynamics rely on the accuracy of the solver to capture these subtle flow structures in areas where the overall flow is very complex. In the example below Flow360 accurately captured the design delta Cd caused by a small change to air-intake. This was particular challenging as it is located near the wheel well. With Flow360 you can have confidence in your results to make the right decisions.

AI-Enhanced Performance Insights

The integration of AI technology into Flow360 provides NIO with enhanced insights that are crucial for optimizing vehicle aerodynamics. Flow360’s AI-driven models don’t just predict drag reduction but also offer detailed surface pressure distributions, allowing engineers to understand how airflow interacts with vehicle surfaces in granular detail. Additionally, the AI provides uncertainty quantification, ensuring engineers can trust the results and make decisions with confidence.

AI-Driven Features of Flow360

-

Aerodynamic Predictions: AI models predict vehicle performance with remarkable accuracy, enabling engineers to make design decisions without the need for lengthy iterative testing.

-

Surface Pressure and Flow Analysis: Detailed insights into how airflow interacts with the vehicle help NIO engineers optimize specific design elements, reducing drag and improving efficiency.

-

Uncertainty Quantification: The AI model also quantifies prediction uncertainties, providing clarity on result reliability.

Impact of GPU-Native CFD with AI Integration

-

Speed: Simulations that once took hours or days are now completed in seconds, enabling rapid testing of design variations.

-

Accuracy: The AI model consistently delivers results with ±3 counts of drag deviation, providing engineers with reliable data for faster decisions.

-

Optimization: With AI, NIO can explore more design concepts, leading to quicker identification of optimal configurations and more informed decision-making.

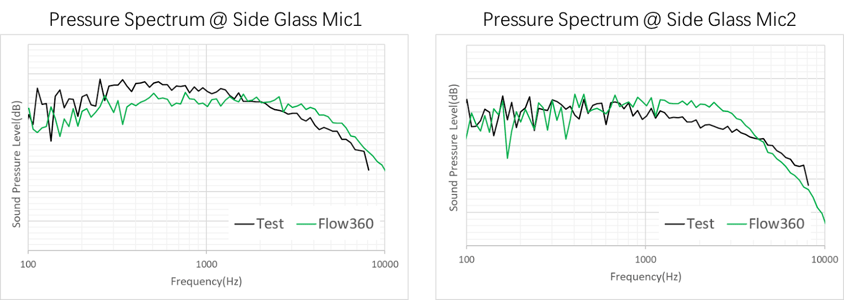

Multiphysics for Aerodynamics and Aeroacoustics

A key problem for many Automotive OEM’s is predicting and managing NVH. As consumers get more sophisticated there is increasing demand for today’s to be quiet during operation. It’s a sign of quality and is expected across the full vehicle range. Compound this with a growing trend to more EVs and the typical powertrain is a thing of the past. EV powertrains have reached a new level of quiet, making wind noise in the vehicle cabin a key area of concern. Flow360 can solve this challenging problem. With a very high fidelity, low dissipation scheme and FWH embedded in the solver, Flow360 can accurately determine the Aeroacoustics of the vehicle. The figures below show validation of Flow360 accurately capturing the pressure spectrum on driver’s side glass as compared to physical test. A key area for driver comfort. You can’t get aeroacoustics right if you don’t have aerodynamics right. With Flow360 you have the ability to address both issues in one Solver helping the Aerodynamicist and NVH Engineer work together on the same design.

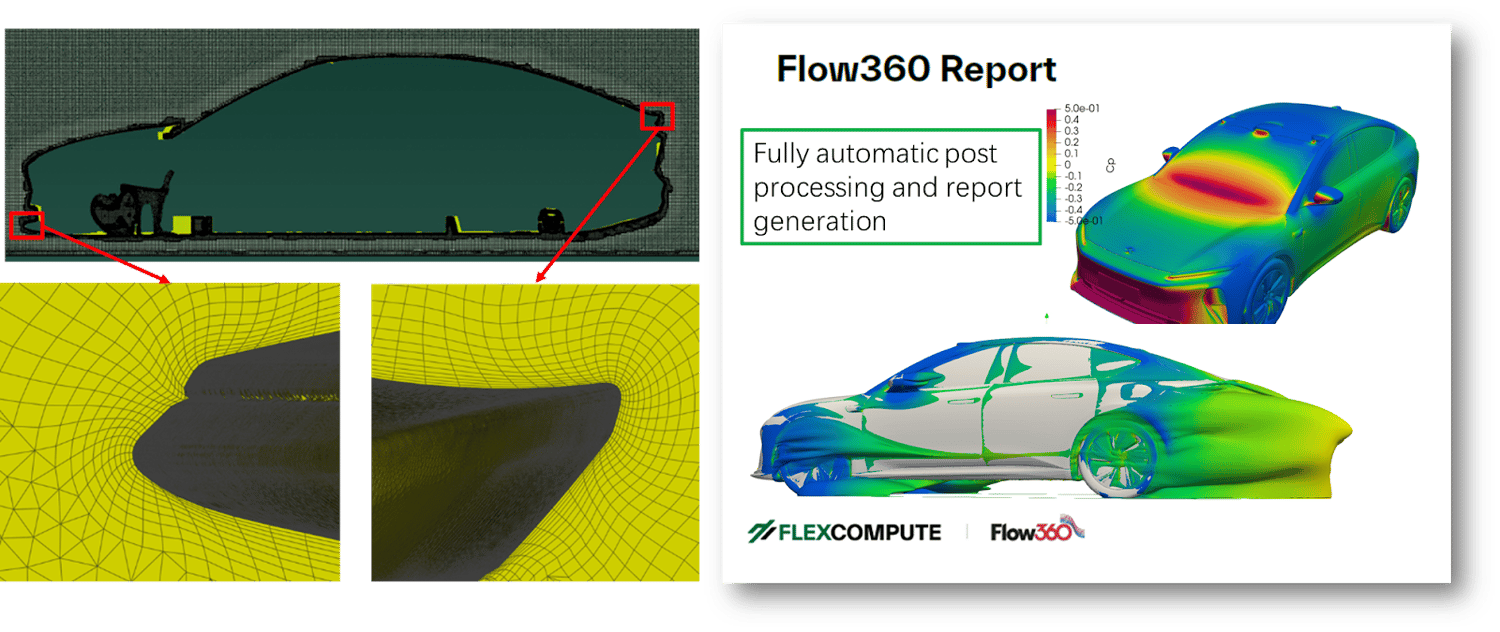

Automatic End-to-End Workflow

One of the challenges in any simulation environment is pre/post-processing. Getting the CAD representation of the vehicle into the Simulation workflow and building the appropriate surface and volume mesh to support an efficient process and get consistent accurate results. Then post-processing the results to compare engineering quantities of interest which support decision making. Often these steps in a simulation workflow can take hours if not days. Flow360 addresses these issues in two important ways. First Flow360 offers a fully automatic volume mesh generation, developed for speed and mesh consistency on complex shapes. For the NIO case we meshed a complex Auto Geometry with 80 Million cells in less than 20 minutes. Over 3x faster than competing meshing tools.

Flow360 offers an auto report generation feature that can be customized to fit your needs/standard. This enables consistent comparison of simulation results in a fully automatic workflow.

Accelerating the Design Process

The most significant benefit of Flow360’s AI-powered CFD solver is the speed at which engineers can evaluate design iterations. Previously, NIO’s teams would spend days testing and analyzing design concepts. Now, they can complete this in minutes, allowing for rapid decision-making and accelerated development cycles.

Flow360 has radically streamlined NIO’s product development workflow by automating predictions and offering real-time simulation results. Engineers can now quickly evaluate multiple design alternatives and select the most promising configurations, optimizing the vehicle design process for both performance and energy efficiency.

The Impact on NIO’s EV Development

Flexcompute’s Flow360 has allowed NIO to accelerate its design cycles, enhance vehicle performance, and streamline its product development process. With Flow360’s speed, accuracy, and AI-enhanced insights, NIO can now develop smarter, more sustainable vehicles, bringing innovation to the forefront of electric mobility.

Key Outcomes for NIO:

-

Accelerated Development: Faster simulation times have enabled NIO to shorten R&D timelines, bringing new models to market more quickly.

-

Enhanced Vehicle Performance: Optimized aerodynamic designs lead to better energy efficiency, longer range, and superior driving dynamics.

-

Streamlined Decision-Making: The AI-enhanced workflow provides faster insights and better data-driven decisions, leading to the optimum design faster.

Pioneering the Future of EV Design

The collaboration between NIO and Flexcompute sets new standards for aerodynamic simulation in the automotive industry. By combining high-fidelity CFD simulation with cutting-edge AI technology, this partnership has empowered NIO to design vehicles that are not only high-performing but also optimized for sustainability and energy efficiency. As NIO continues to innovate and lead in the smart EV market, Flexcompute’s Flow360 plays a critical role in shaping the future of automotive design—one that embraces the power of AI, high-performance computing, and rapid innovation.