The REGENT Seaglider

REGENT’s“seaglider” is a fully electric vehicle that utilizes a blown wing and hydrofoils for takeoff from the water, instead of gas-powered engines and a hull used by traditional seaplanes. Seagliders are a much more efficient alternative to traditional hopper flights and a much faster alternative to traditional ferry routes. Such an efficient commuter transport will greatly benefit passengers traveling between coastal cities.

Design with Detailed Flow Insights

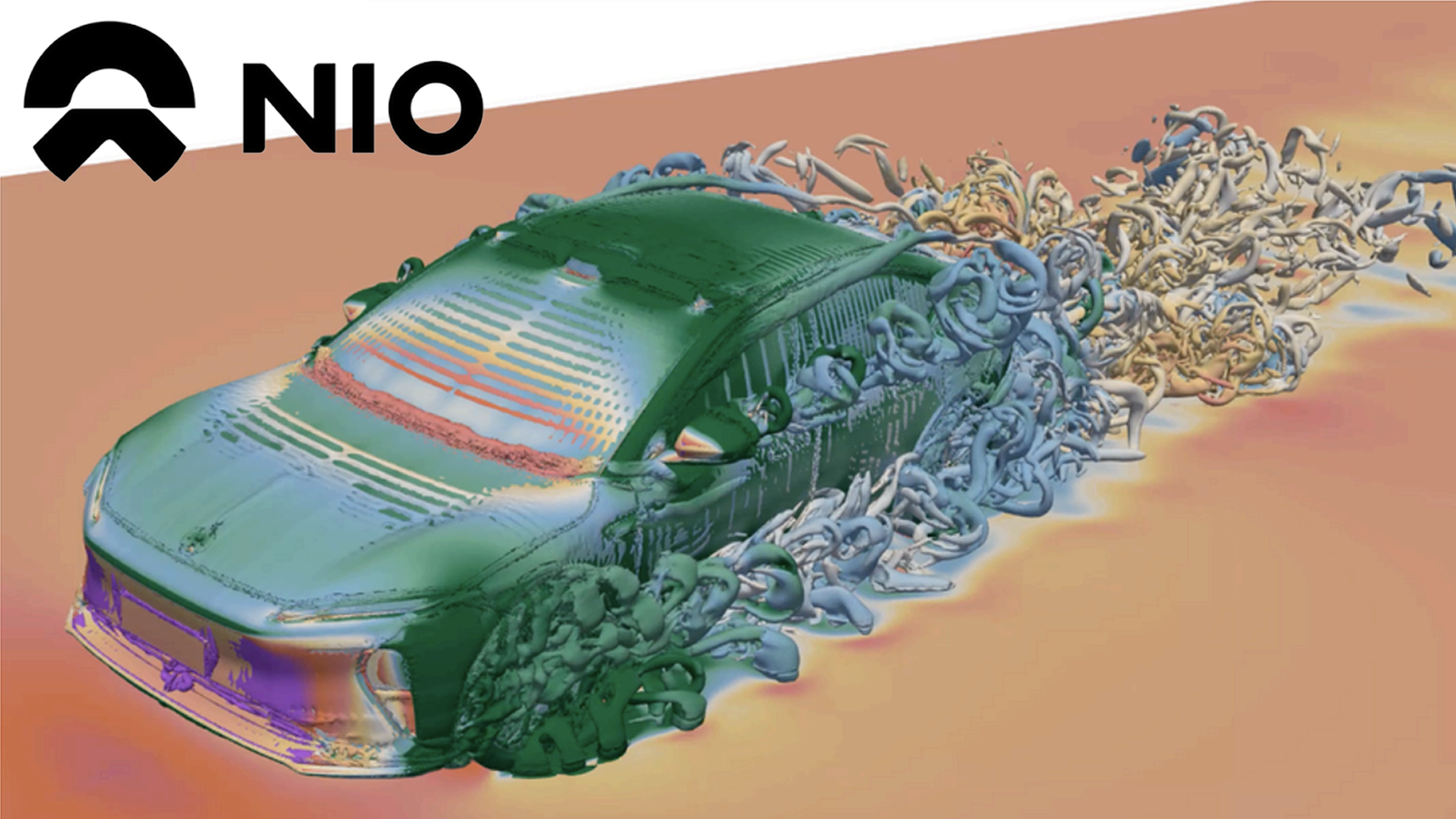

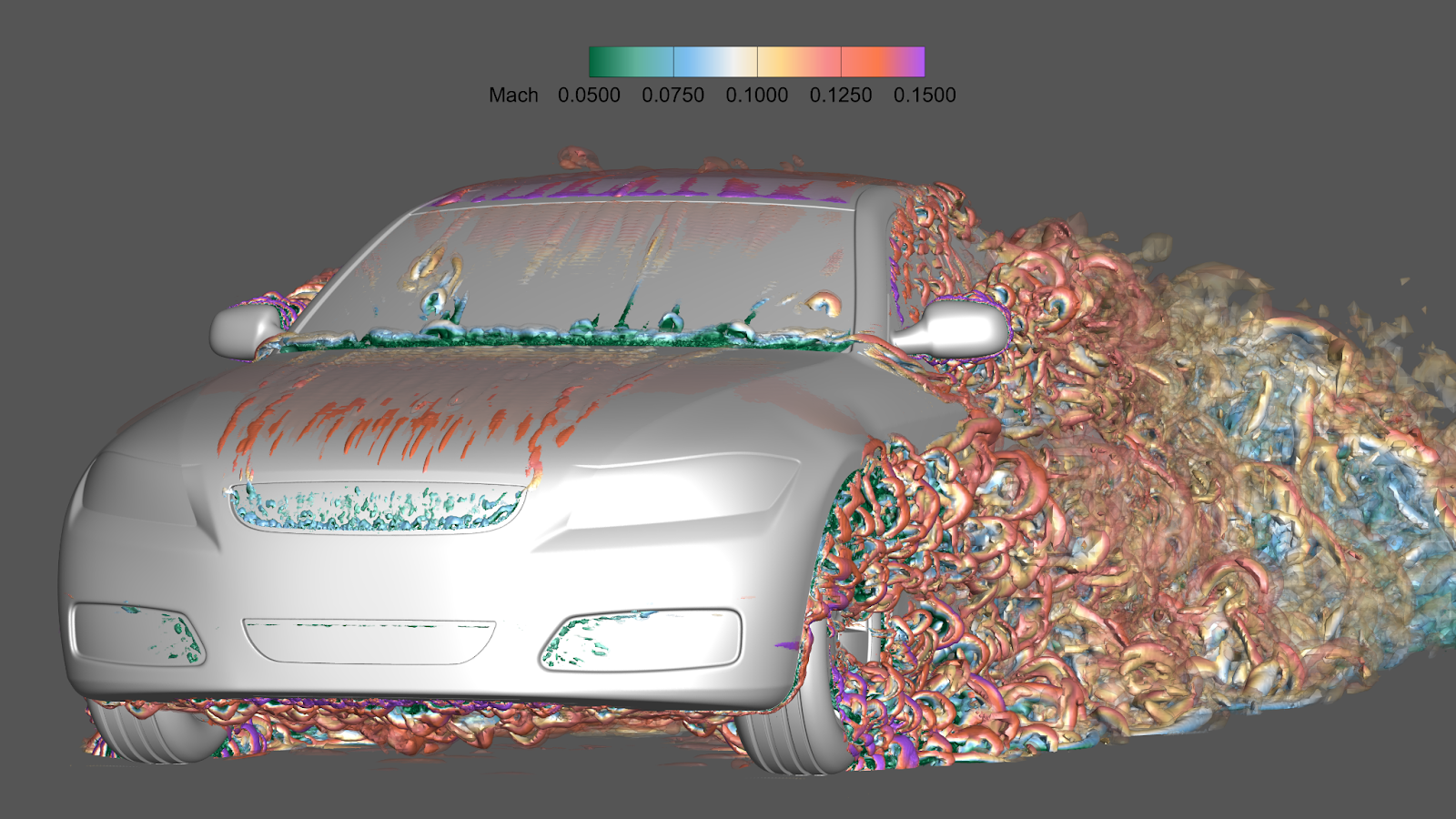

While flying in ground effect, the seaglider’s aerodynamics are important for precise flight control capability, passenger comfort (acoustics, vibration) and safety. Addressing these design challenges requires leveraging a world class aerodynamics group using state-of-the-art simulation technologies. A revolutionary CFD solver like Flow360 provides a distinct advantage for REGENT’s engineering staff, enabling them to analyze more complex flight conditions and flow physics in significantly less time.

Our experience working with the Flow360 team has been collaborative and responsive to our fast design mentality at REGENT pushing the state of the art with speed and accuracy. Couldn’t be happier with this new simulation technique.

Bryan Baker Chief Engineer Vehicle Physics

Successful Prototypes from Digital Designs

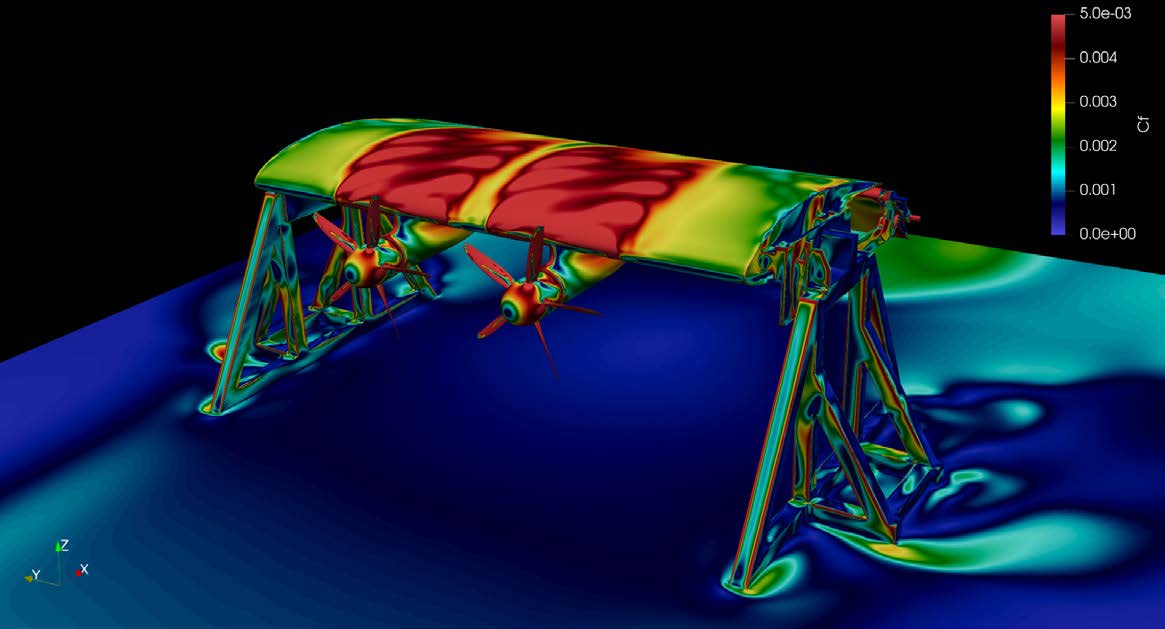

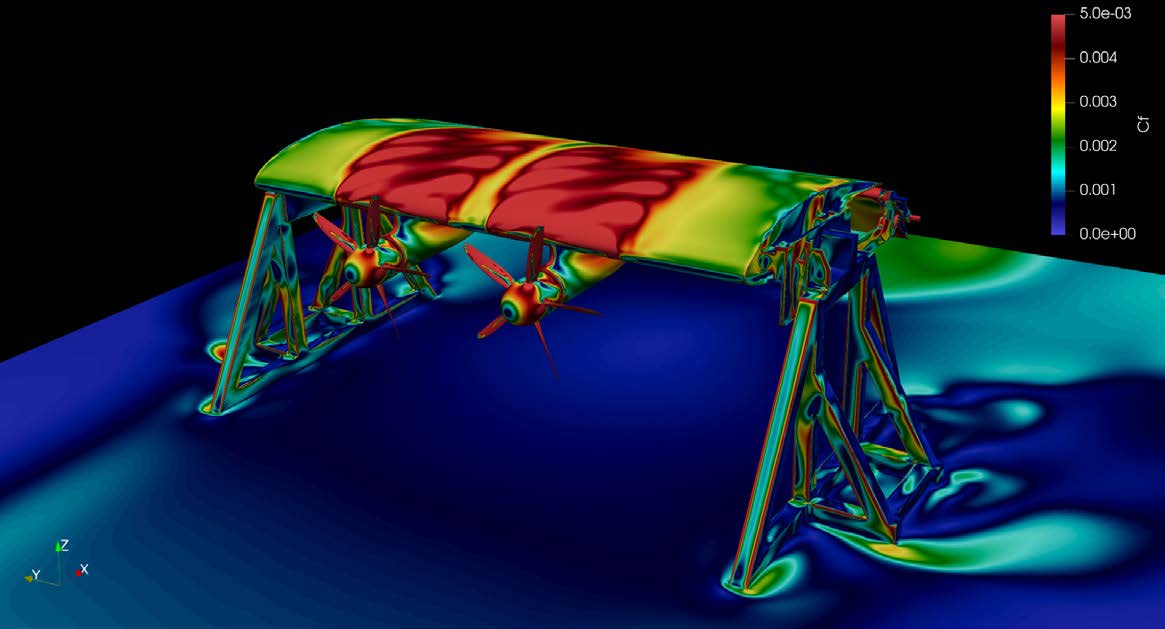

Building on a successful design process, REGENT continues to emphasize digital and physical testing for their first full-scale human-operated vehicle, Paladin. REGENT is validating CFD methodologies with wind tunnel tests of a full-scale segment of their blown wing to ensure accuracy and build correlations involving digital simulation results. The test article's instrumentation reads surface static pressures, motor torque and power, as well as all body forces and moments. By correlating the same geometry and operating conditions both in the wind tunnel and in CFD, REGENT can increase certainty in digital designs and achieve success with its prototype builds.

Simulation results with Flow360 are achieved in less than 6 hours. The model has more than 150M elements and is run with as little as 1° of rotation per time step for more than 25 revolutions.

By leveraging Flow360’s unprecedented speed and accuracy, REGENT engineers can confidently and in record time simulate complex flows. The resulting flow insights allow for confirming assumptions, preemptively addressing concerns, and preparing for successful test campaigns.

-1.jpg)