Inverse design has revolutionized how photonic devices are engineered, enabling researchers to discover innovative structures that meet complex performance goals. Traditionally, inverse design workflows have relied on manual parameter sweeps or heuristic optimization algorithms, which can be time-consuming and computationally expensive, especially for large-scale photonic structures.

Tidy3D changes the game by bringing automatic differentiation (AD) to the world of electromagnetic simulations, providing an exceptionally efficient route for gradient-based optimization in photonic inverse design. But how exactly does automatic differentiation work in Tidy3D, and why does it matter?

The Challenge of Gradient Calculation

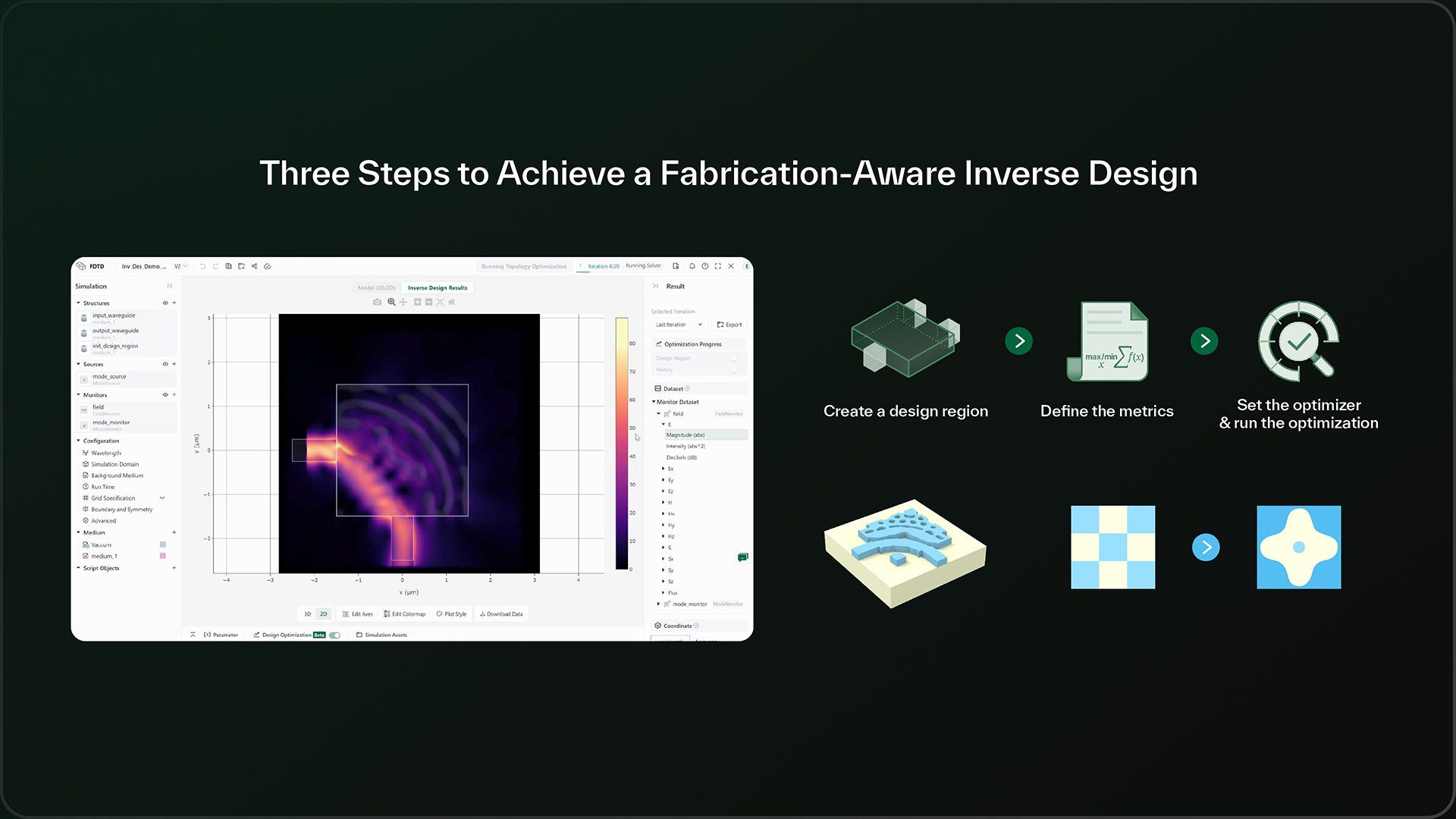

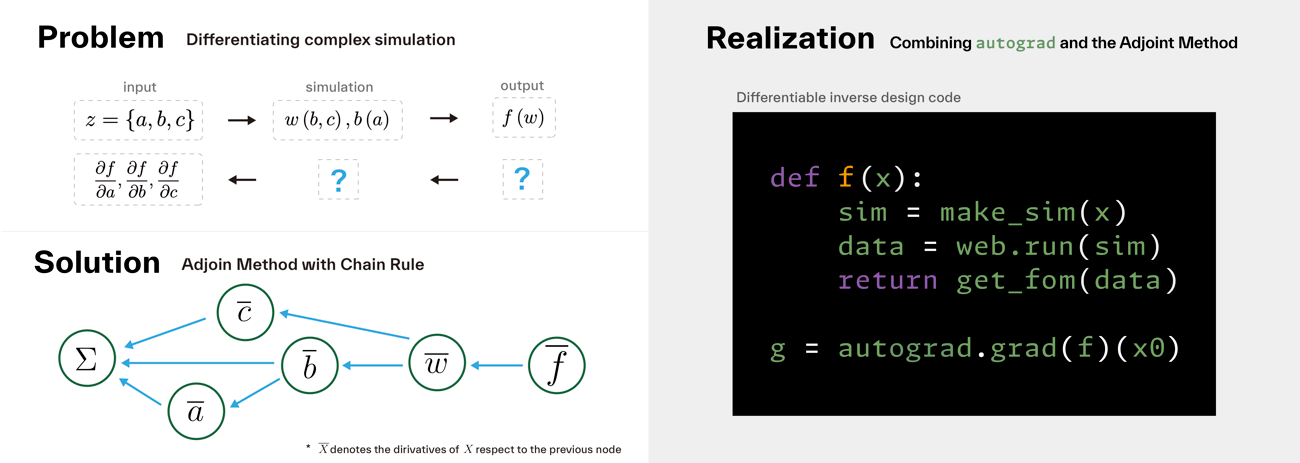

At the heart of inverse design lies optimization: tweaking geometry or material parameters to maximize or minimize a specific objective (e.g., transmission, absorption, resonance frequency). To do this efficiently, optimizers need gradients—sensitivity information about how small changes in each design variable affect the objective.

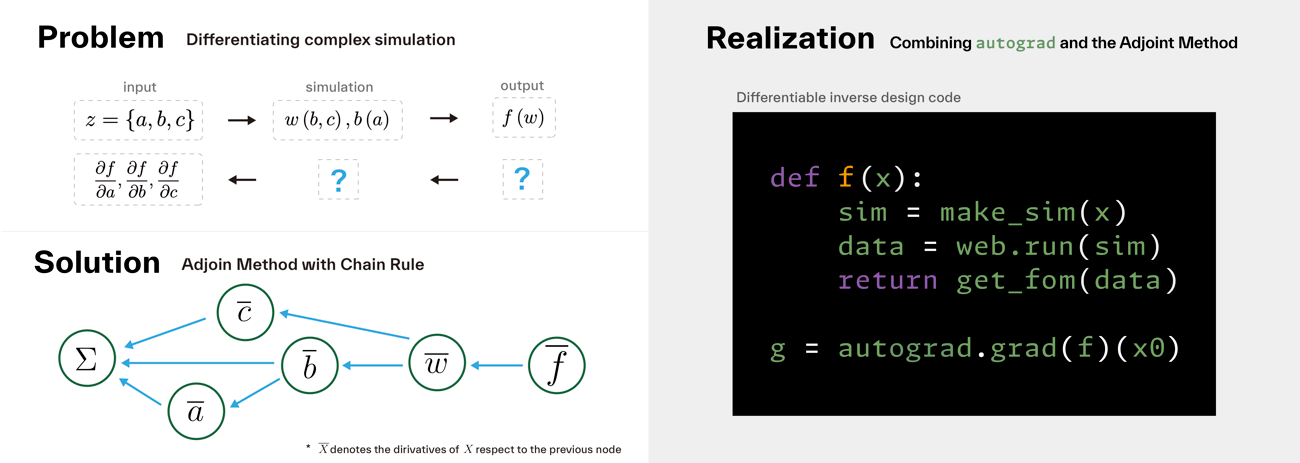

Finite-difference methods can estimate gradients but require one extra simulation per parameter, leading to prohibitive computation time for large systems with many variables. This is where automatic differentiation shines.

How Automatic Differentiation Works in Tidy3D

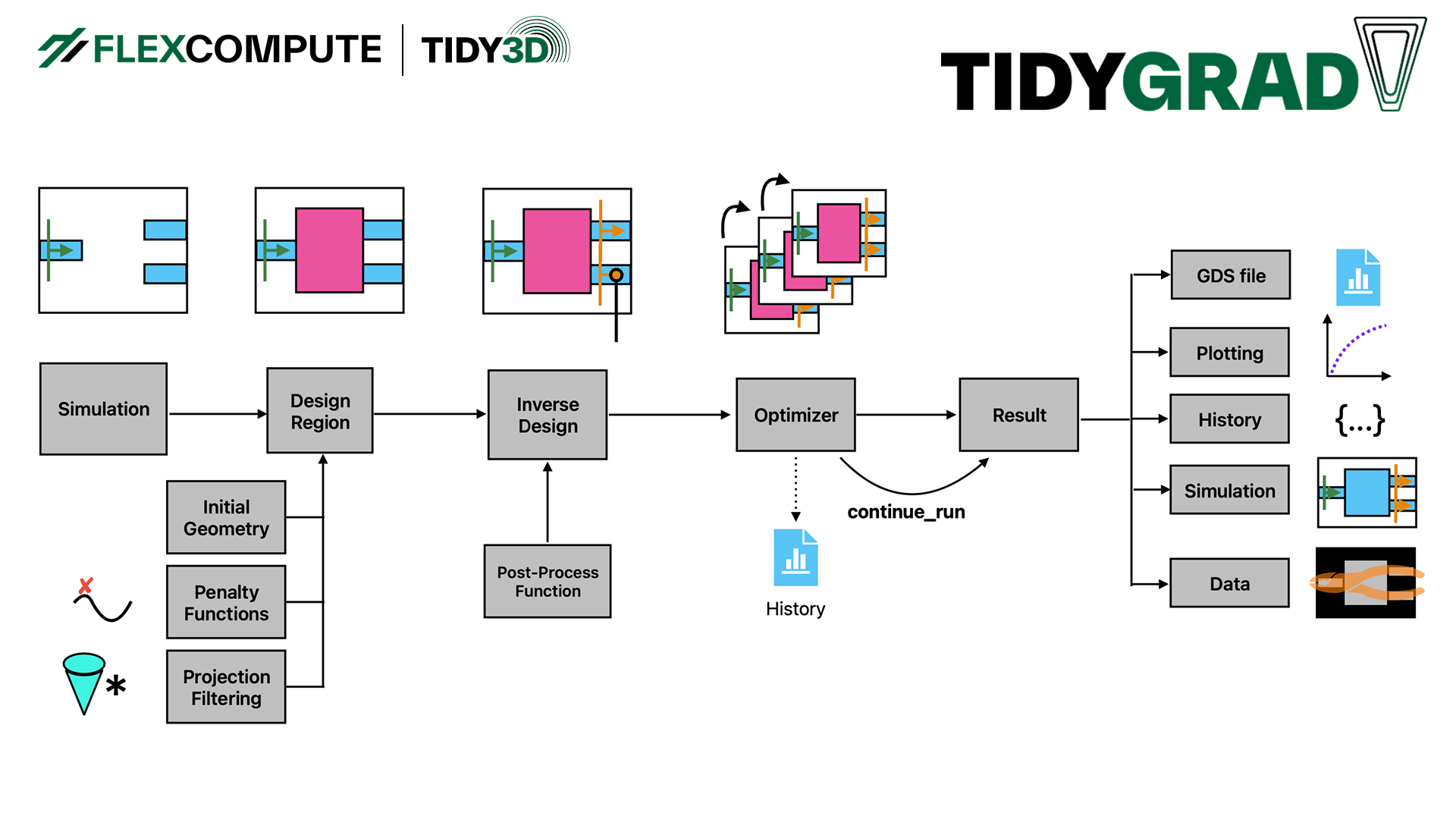

Tidy3D leverages automatic differentiation by embedding the entire electromagnetic simulation into a computational graph, akin to how modern machine learning frameworks (like TensorFlow or PyTorch) work. Every mathematical operation—from defining materials to solving Maxwell’s equations—is recorded in this graph.

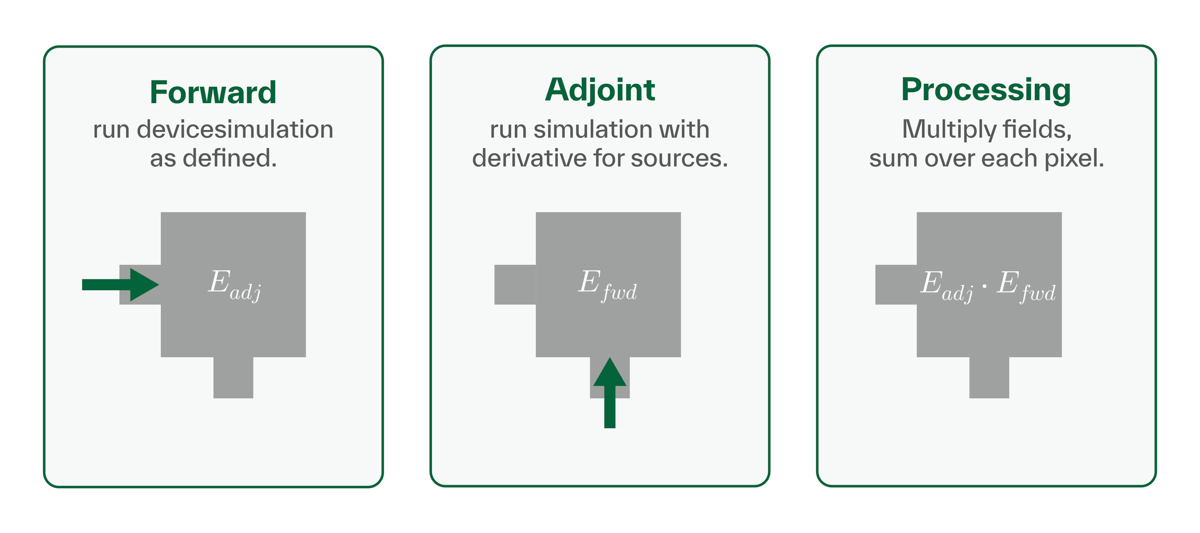

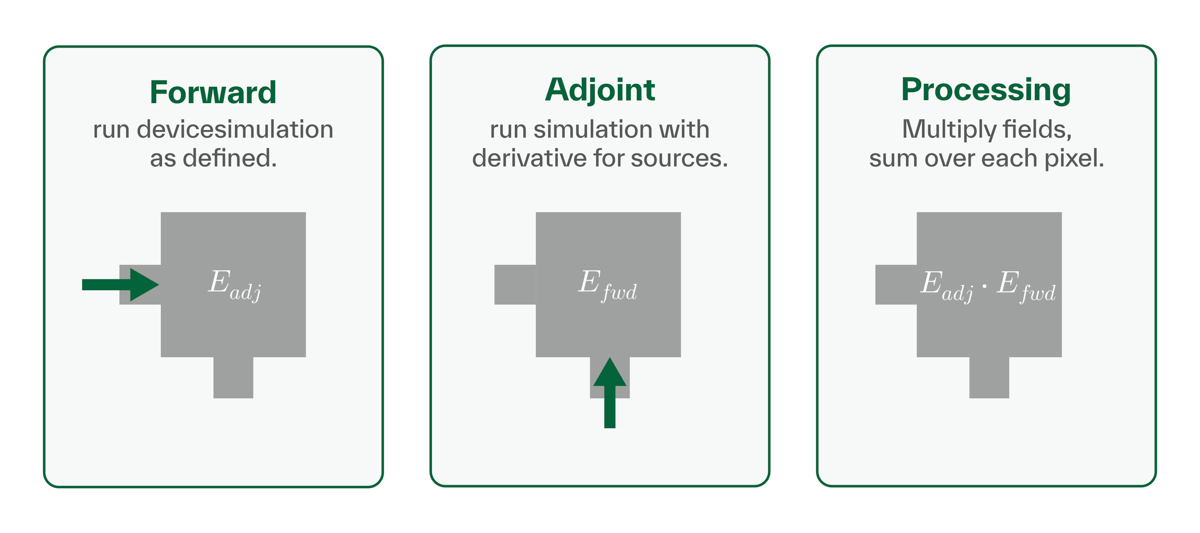

When you define an objective (say, optimizing light transmission through a structure), Tidy3D can trace backward through this graph using the adjoint method to efficiently compute gradients of the objective with respect to all design parameters in a single additional simulation.

In practical terms, this means:

-

1 forward simulation for the nominal design.

-

1 adjoint simulation for all gradients.

-

Thousands of times faster than traditional finite-difference approaches for large-scale problems.

Why It Matters

For photonic engineers and researchers, Tidy3D’s automatic differentiation dramatically reduces the computational cost of inverse design, making ambitious projects—such as optimizing high-Q cavities, metasurfaces, or photonic crystal structures—not only possible but practical.

Additionally, because Tidy3D’s inverse design features are seamlessly integrated with its Python API, users can:

-

Combine electromagnetic simulations with other physics (e.g., thermal, electrical) in multi-physics workflows.

-

Customize objectives, constraints, and optimization strategies easily.

-

Leverage GPU acceleration for both forward and adjoint simulations.

Real-World Impact

This approach has already been demonstrated when designing compact, high-efficiency photonic components like mode converters, couplers, and wavelength filters. For startups, research labs, and industrial teams, it means faster iteration cycles, reduced reliance on manual trial-and-error, and a streamlined path to high-performance photonic designs.

Learn More

Explore the inverse design examples in the Example Library.

Learn more about how automatic differentiation works in Tidy3D inverse design.